The Technology Manufacturing of Precooked Corn Flour - Unlocking Nutritional and Culinary Potential

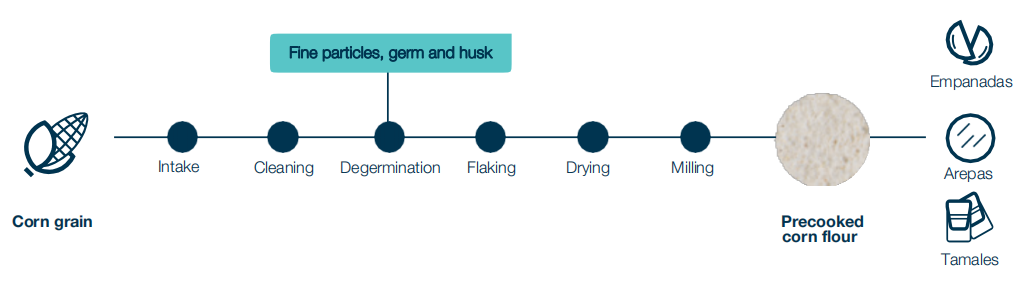

The manufacturing of precooked corn flour involves a series of sophisticated technologies that transform raw corn into a versatile and valuable food product. This process not only preserves the nutritional benefits of corn but also adds convenience and new possibilities for culinary uses.

Raw Material Selection and Preparation

- The starting point is the careful selection of high-quality corn. Varieties are chosen based on their starch content, flavor, and overall quality characteristics. The corn is then cleaned to remove any impurities such as dirt, stones, and other foreign materials. This ensures that only pure corn enters the manufacturing process.

- After cleaning, the corn may be soaked in water for a certain period to soften it and prepare it for the next steps. This soaking process can also help to activate certain enzymes in the corn, which can have a positive impact on the final product's quality and nutritional properties.

Cooking and Precooking Processes

- One of the key technologies in precooked corn flour manufacturing is the cooking method. The corn is typically cooked using either steam or hot water. Steam cooking is a popular choice as it allows for even heat distribution and helps to retain the natural flavors and nutrients of the corn. The cooking time and temperature are carefully controlled to achieve the desired level of precooking.

- During the precooking process, the starch in the corn undergoes a series of changes. It gelatinizes, which means the starch granules absorb water and swell, making the corn easier to grind and improving its digestibility. This precooked state also gives the final corn flour a unique texture and functionality when used in various food applications.

- Some advanced manufacturing processes may use pressure cooking techniques to further enhance the gelatinization of the starch and improve the overall quality of the precooked corn. This can result in a more uniform and stable product with better cooking and textural properties.

Drying and Milling

- After precooking, the corn needs to be dried to the appropriate moisture content. This is usually done using specialized drying equipment such as spray dryers or drum dryers. The drying process is critical as it affects the shelf life and storage stability of the final product. If the moisture content is too high, the corn flour may be prone to spoilage, while too low a moisture content can lead to a hard and brittle product.

- Once the corn is dried to the desired level, it is milled into a fine powder to produce the precooked corn flour. The milling process can use different types of mills, such as hammer mills or roller mills, depending on the desired particle size and texture of the final product. Fine milling can result in a smoother and more uniform corn flour, which is suitable for applications where a texture is required, such as in baby food or certain baked goods. Coarser milling can be used for products where a more rustic texture is desired, like in some traditional corn-based dishes.

Quality Control and Testing

- Throughout the manufacturing process, strict quality control measures are in place. Samples are taken at various stages to test for parameters such as moisture content, particle size, color, and nutritional composition. This ensures that the precooked corn flour meets the established quality standards and is consistent in its properties.

- Microbiological testing is also essential to ensure the product is free from harmful bacteria, molds, and other contaminants. Advanced testing methods and equipment are used to detect any potential issues and maintain the safety and quality of the precooked corn flour.

- Quality control also extends to the packaging stage. The corn flour is packaged in suitable materials that protect it from moisture, light, and other factors that could affect its quality during storage and transportation.

Nutritional Enhancement and Fortification (Optional)

- In some cases, the manufacturing process may include steps to enhance the nutritional value of the precooked corn flour. This can involve fortification with vitamins and minerals, such as iron, zinc, and vitamin B complex. These additions can help to address nutrient deficiencies and make the corn flour a more complete and nutritious food source.

- Additionally, techniques may be used to preserve or even increase the levels of natural nutrients in the corn, such as antioxidants and dietary fiber. For example, gentle processing conditions can be employed to minimize the loss of these beneficial components during manufacturing.

Applications and Culinary Versatility

- The precooked corn flour manufactured through these technologies has a wide range of applications in the food industry. It is commonly used in the production of ready-to-eat cereals, snack foods, bread, and pastries. Its precooked nature means it requires less cooking time and effort when used in recipes, making it a convenient choice for both consumers and food manufacturers.

- In the culinary world, precooked corn flour can be used to make traditional dishes such as cornbread, polenta, and tortillas with ease. It can also be used as a thickener in soups, stews, and sauces, adding a unique flavor and texture. The versatility of precooked corn flour allows for creative and innovative food product development, meeting the diverse demands of consumers for delicious and nutritious food options.

In conclusion, the technology manufacturing of precooked corn flour is a complex and sophisticated process that combines scientific knowledge and engineering expertise. It results in a product that offers both nutritional value and culinary convenience, making it an important ingredient in the modern food industry and a valuable addition to our diet. By continuously improving and innovating these manufacturing technologies, we can look forward to even better quality precooked corn flour and more exciting food applications in the future.