-

+86-371-86159555

Introduction:

The global demand for maize flour and meal products is on the rise, driven by growing consumer preferences for healthier and more sustainable food options. Setting up a maize milling plant can be a lucrative venture, but it's essential to understand the costs involved before diving in. China Win Tone Machinery, a renowned company in the industry, is here to help you navigate through the complexities of maize milling plant setup costs.

Section 1: Initial Investment

1.1 Land and Property

The first step is to secure a suitable location for your maize milling plant. Factors to consider include accessibility, infrastructure, and zoning regulations. The cost of land acquisition or lease will depend on the location and size of the property.

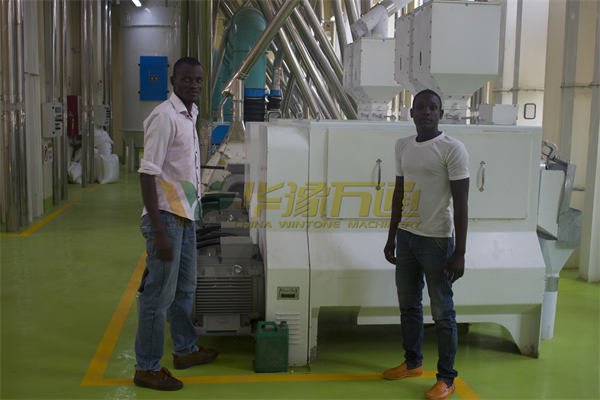

1.2 Equipment and Machinery

The heart of your maize milling plant is the equipment and machinery. China Win Tone Machinery offers a wide range of high-quality maize milling machines and accessories. The cost of equipment will depend on the scale of your plant and the technology you choose. Key equipment includes:

* Maize cleaning machines

* Grinding machines

* Sieving machines

* Refining machines

* Packaging machines

1.3 Building and Infrastructure

You will need to construct a suitable building to house your plant, including storage facilities, workshops, and office space. The cost of construction will depend on the size of the building, materials used, and local labor costs.

1.4 Labor and Manpower

Hiring skilled and experienced labor is essential for the smooth operation of your maize milling plant. Factors to consider include salaries, benefits, and training costs.

Section 2: Ongoing Costs

2.1 Operational Costs

* Electricity and Water Bills: The cost of utilities will depend on the size of your plant and the efficiency of your equipment.

* Maintenance and Repair: Regular maintenance is crucial to ensuring the longevity of your machinery. Budget for periodic maintenance and repair costs.

* Raw Material Costs: The cost of maize raw material will depend on market prices and your supplier.

2.2 Transportation and Logistics

Consider the cost of transportation for raw materials, finished products, and waste disposal. Additionally, plan for shipping fees if you're exporting or importing products.

2.3 Marketing and Promotion

Invest in marketing and promotional activities to build brand awareness and increase market share. Costs may include advertising, website development, and attending industry events.

Section 3: Tips for Cost-Effective Setup

3.1 Buy High-Quality Machinery

Investing in high-quality, durable machinery will save you money in the long run by reducing maintenance and repair costs.

3.2 Optimize Plant Layout

An efficient plant layout can help reduce operational costs and increase productivity. Consult with an expert to optimize your plant's layout.

3.3 Streamline Production Process

Implementing advanced production techniques and automation can help reduce labor costs and improve output.

3.4 Negotiate Pricing

Negotiate pricing with suppliers, contractors, and lenders to get the best deals possible.

Conclusion:

Understanding the costs involved in setting up a maize milling plant is crucial for successful entrepreneurship in this industry. China Win Tone Machinery is a reliable partner for your maize milling plant project, providing high-quality machinery, professional consultations, and comprehensive after-sales service. With the right planning and execution, you can turn your maize milling plant dream into a profitable reality.

+86-371-86159555

86635803

No. 57 Science Avenue

Zhengzhou, Henan, China

7*24 hours

Human services