-

+86-371-86159555

Function and Features Introduction:

Our 20Ton/Day corn milling plant design includes screening, stone removing, peeling, polishing, milling, brushing, pneumatic transportation, electric control and products packing. This is a small scale of maize milling line and can ensure maize flour yield and quality with low energy consumption and investment.

Main Equipments of 20Ton/day Corn Milling Plant It has a maize cleaner, moisture dampener, 1 degerminator, 4 roller mills, 2 double sifters, an auto packing system and all the connecting pipes are stainless steel.

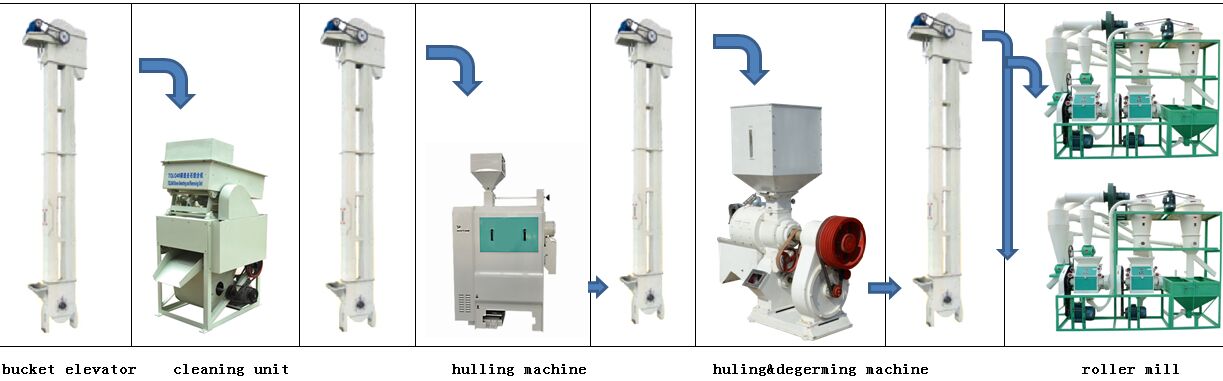

20T/Day corn milling plant working process:

1. Maize Cleaning unit: To clean sand,stone,and other impurities from raw corn.

2. Maize peeling machine: This machine is designed for maize hulling,the emery rollers can remove bran without adding water into maize.

3. Maize degerming machine: this machine is a special equipment which is mainly applied for corn hulling, de-germinating and polishing

4. Maize milling machine: Lower energy consumption and high efficiency low cost. Designed to provide top safety and sanitation. Flexible adjustment, easy installment and operation. High degree of automation.

5. Bucket elevator: used for materal transporting. low noise, high efficiency, and convenient operation and maintenance.

6. Magnetic separator: remove metal impurities.

7. Measuring and Packing Machine . It can pack maize flour or grits 5kg/bag.10kg/bag.50kg/bag as you required.

Corn Roller Mill:

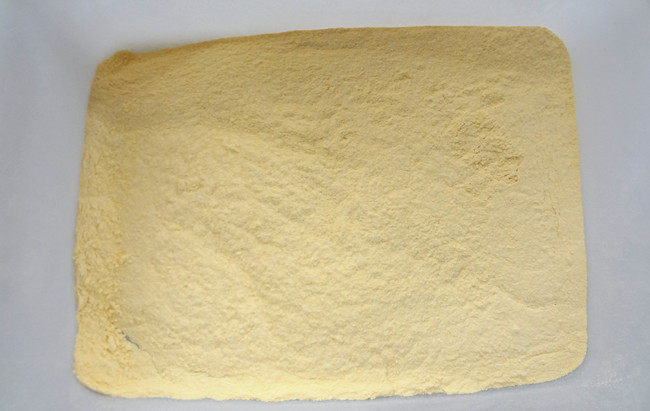

Corn Flour:

20T Corn Milling Plant Maize Mill Plant Technical Parameter:

1. Capacity: processing maize 20T/Day.

2. Raw material: white maize or yellow maize

3. Final products: super white maize meal, maize flour, and grits.

4. By-product: Animal feed.

| Processing Capacity | Power | Power Consumption for Tons of Material | Yield | Workshop Size | |

| KW | KW/HOUR | T/24 HOURS | L×W×H/M | ||

| 20T | 72 | 58-60 | 20T | 20×5×5(line structure) | |

| 16×5×6(steel structure) | |||||

| 30T | 108 | 58-60 | 30T | 24×5×6(line structure) | |

| 30×5×5(steel structure) | |||||

| 50T | 172 | 56-58 | 50T | 35×5×7(steel structure) | |

| 100T | 346 | 56-58 | 100T | 40×7×8(steel structure) | |

Features of our maize milling lines:

1.Water saving, power saving.

2.Clean and pure final flour.

3.Flour fineness can be adjusted.

4.Low investment!

5.Automatic production process.

6.Free warranty.

7.Field installation and training!

8.7*24 hours after-sales service!

End products index:

1.Corn flour fineness:40-200 meshes (the flour fineness can be adjusted)

2.Sand content:<0.02%

3.Magnetic metal content:< 0.003

4.Moisture storage:13.5-14.5%

5.Fat content:0.5—1%

6.Appearance and taste: bright color, fine powder, high quality and pure taste.

Yellow maize processing:

White maize processing:

Overseas Offices:

1.Office in Uganda:

Address: Plot 27. Luthuli Avenue, Buglobi P.O.Box 8338, Kampala, Uganda

Contact: Sophia

Email: wintone16@wintonemachinery.com

2.Office in Kenya:

Address: Mudher Industrial Park, Off Mombasa Road, Next to Soham Petrol Station, Nairobi, Kenya

Contact: Emma

Email: info@wintonemachinery.com

3.Office in Ethiopia:

Address: No.4 Floor, Yobex Building, Mexico Area, Addis Ababa, Ethiopia

Contact: Jaspher

Email: wintone16@wintonemachinery.com

+86-371-86159555

86635803

No. 57 Science Avenue

Zhengzhou, Henan, China

7*24 hours

Human services