-

+86-371-86159555

Automatic instant noodles production line is controlled automatically from flour feeding to the final products with less manual operation. The operators only need to observe, monitor and adjust the equipments, which saves a lots of labors and reduce the cost.

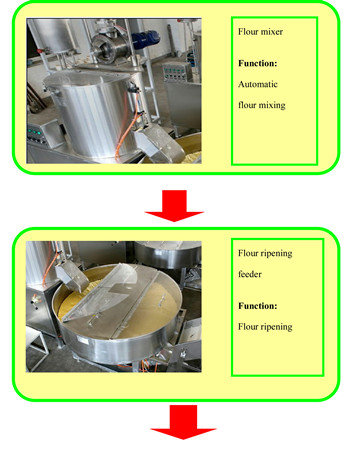

The automatic process:

Flour insert --- flour mixing --- paste ripening --- paste lifting --- paste feeding --- first extrusion --- second extrusion --- vermicelli forming --- rationing cutting --- combing ---adjusting --- steaming --- drying --- cooling ---inspecting --- packaging --- production conveyor

Output:80000packs for 24hours, 5.6tons/24 hours

Model: SNTNCS8

Detailed technological process of the automatic instant noodles production line:

1. Flour mixture equipment:

mixture bucket diameter ∮760㎜

bucket volume 280L

motor power 4Kw

dimension1160 x 760 x 1625㎜

Material stainless steel, carbon steel

2. Stainless steel:

mixture bucket diameter ∮900

liquid mixture barrel:

bucket volume 400L

motor power 0.55Kw

dimension ∮1140 x 1500㎜

Material stainless steel

3. Liquid measuring pot:

liquid monitor meter 1

bucket diameter ∮320㎜

volume bucket 32L

dimension∮350 x 2450㎜

Material stainless steel4. Pump:0.37Kw

5. Flour ripening feeder:

power 1.5Kw

diameter ∮1200mm

dimension1200 x 1200 x 940

Material stainless steel, carbon steel, etc.

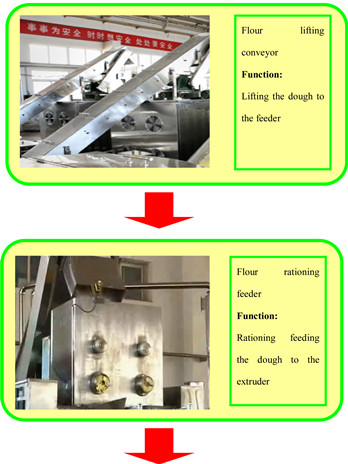

6. Flour lifting conveyor:

conveyor width 350㎜

lifting height 2550㎜

reducer power 0.75Kw

The dimension 3600 x 600 x 3000㎜

Material stainless steel, carbon steel

7. Flour rationing feeder:

Two-head feeder device 1

reducer power 1.1Kw x 2

The dimension 1250 x 1000 x950㎜

Material stainless steel, carbon steel

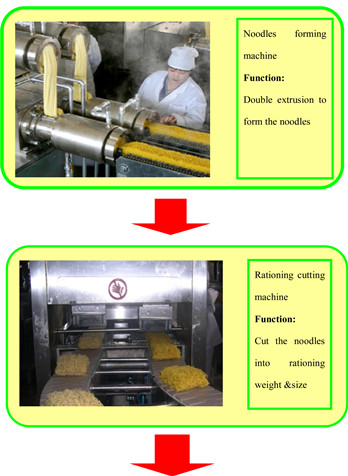

8.Noodles forming machine:

The extruder power 15Kw x4

extruders’ distance 300㎜

The dimension 2530 x 1100 x 1852㎜

Material stainless steel, carbon steel

9. Rationing cutting machine:

insert-conveyor width 180㎜ x 2

insert-conveyor power0.55Kw

air ejector power 0.37Kw

cooling fan power 100W x 12

dimension 3590 x 800 x 1600㎜

Material stainless steel, carbon steel

10. Noodles distributing device:

Power 1.1Kw

Material stainless steel

11. Noodles combining conveyor:

Power 1.1Kw

Material stainless steel, carbon steel, plastic

12. Noodles adjusting machine:

adjusted frequency speed

controlled by the aging tunnel

driving mode by cylinder

dimension 300 x 1170x 1550㎜

Material stainless steel, carbon steel

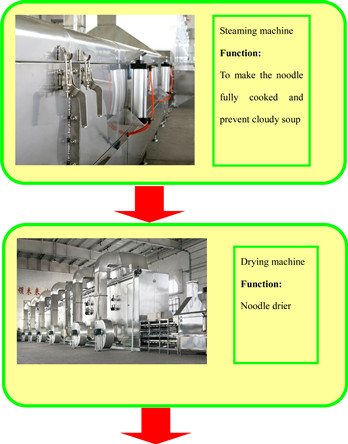

13. Steaming conveyor:

The steaming time 2.5 min

The driving mode

Come from the aging tunnel

The cover-lift cylinder 4

cylinder diameter ∮80㎜

cylinder distance 250㎜

The steam pressure 0.2~0.3Mpa(adjustable) steam consumption 150㎏/h

The dimension 4290 x 1500x 1820mm

Material stainless steel, carbon steel

14. Multiple-level drying tunnel:

The capacity 80000pack/day, 70g/pack

The power 3Kw

The air-heater 4 groups

The air blower power 4Kw x 3

The inner temperature

50℃~80℃(adjustable)

The steam pressure 0.3~0.5Mpa

The steam consumption 230㎏/h

The dimension 1000 x 2800 x 3500mm

Material stainless steel, carbon steel

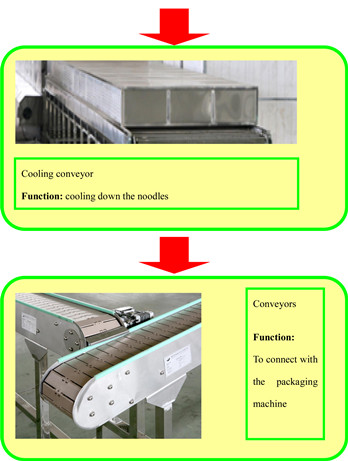

15. Cooling conveyor:

The driving mode

Speed controlled by the drying tunnel

conveyor width 800㎜

The cooling time 3 min

cooling fan power 45 W x 5

The dimension 4800 x 1200 x 1400㎜

Material stainless steel, carbon steel

16. Connection conveyor:

The width of conveyor 150㎜

speed reducer power 0.37Kw

The dimension 2000x 450 x 920㎜

Material stainless steel, carbon steel

17. Inspection conveyor:

conveyor width 150㎜

reducer power 0.37Kw

The dimension 2200 x 450 x 1080㎜

Material stainless steel, carbon steel

18. Production conveyor:

conveyor width 150mm

reducer power 0.37Kw

The dimension 2200 x450 x 820㎜

Material stainless steel, carbon steel

19. 1#electric controlling case

20. 2#electric controlling case

1) Motors, decelerators and most spare parts are adopted the national well-known qualified products;

2) The most critical bearings, cylinders are adopted Japanese well-known products;

3)Touch Screen, PLC using Siemens products;

4 )Frequency converter using Delta products;

5 )Most IDEC,MON qualified electrical components are used and less national qualified products adopted

OUR FACTORY:

PROCESSING WORKSHOP:

CUSTOMER VISIT:

FAIR:

OUR TEAM:

+86-371-86159555

86635803

No. 57 Science Avenue

Zhengzhou, Henan, China

7*24 hours

Human services